At Master Packing and Rubber Company (MPRC), we maintain a broad inventory of gasket sheeting and rolls. We offer Rubber, beater addition, compressed sheets that come in a wide variety of rubber materials, and a range of standard beater-add to a compressed sheet. We also stock PTFE gasket sheets with optional filler materials. Our gasket sheets can fit your specifications and come in various commercial grades. We inventory high-quality gasket materials made with graphite, and our warehouse is stocked with various forms, including pure homogenous sheets and laminates with a wide range of tanged cores, expanded steels, foils, and substrates.

At MPRC, we listen to our customers with the primary goal of delivering a gasket sheet material that meets the customer’s expectations. We stock a wide range of materials to deliver custom gaskets and ensure short lead times. Our experts can help you select the ideal material for your application.

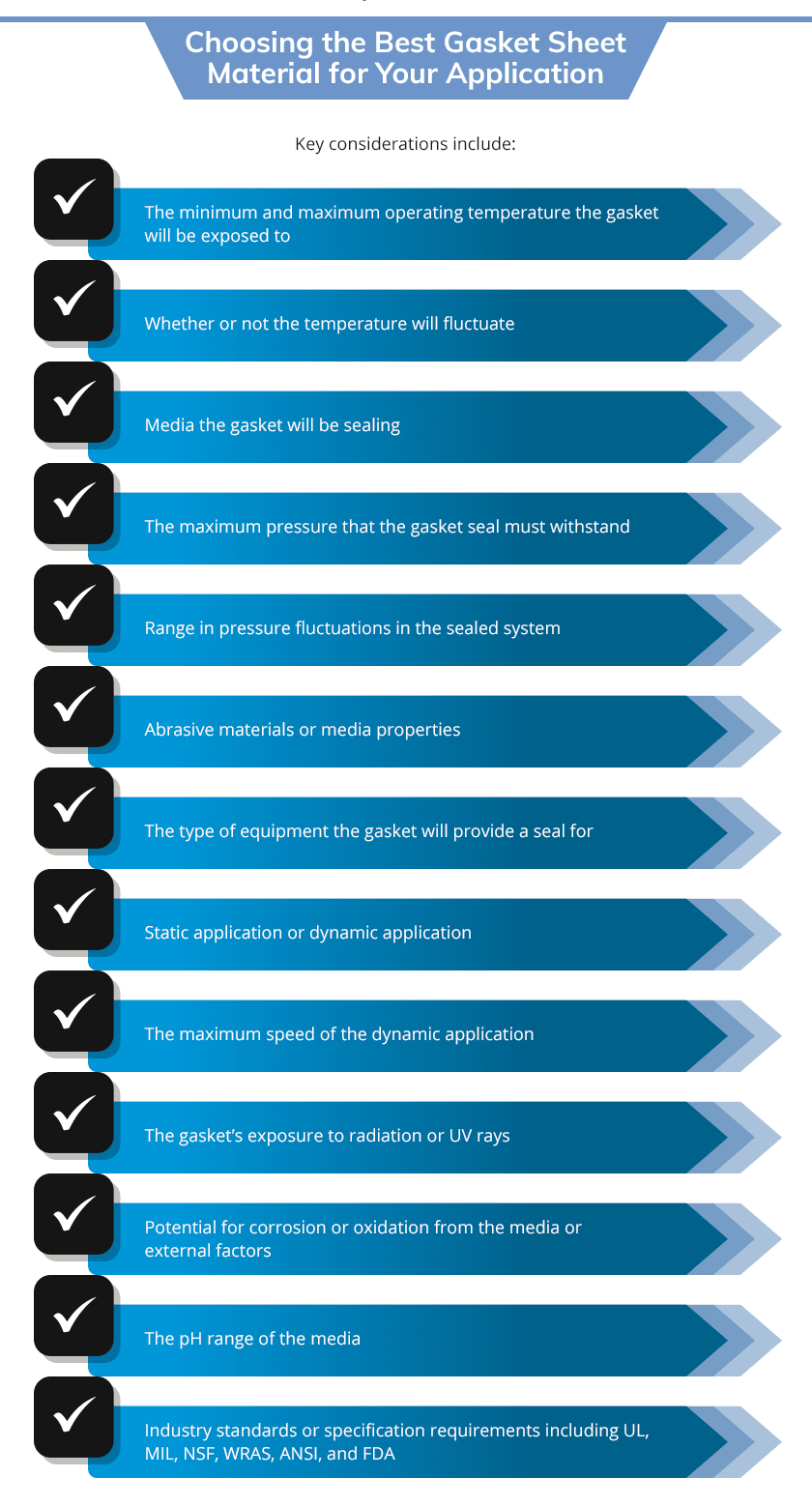

Choosing the Best Gasket Sheet Material for Your Application

Choosing a gasket sheet material that is suitable for your application is essential. To properly perform, gaskets must be resilient and compressible to accommodate mating surface irregularities. The gasket material may also need to prevent fluids or gases from passing through the seams and crevices of the mating surface.

With a wide range of gasket sheet materials available, it’s important to consider the conditions and requirements of your specific application. Finding a material with the ideal properties to suit these factors ensures an effective, long-lasting seal. Key considerations include:

- The minimum and maximum operating temperature the gasket will be exposed to

- Whether or not the temperature will fluctuate

- Media the gasket will be sealing

- The maximum pressure that the gasket seal must withstand

- Range in pressure fluctuations in the sealed system

- Abrasive materials or media properties

- The type of equipment the gasket will provide a seal for

- Static application or dynamic application

- The maximum speed of the dynamic application

- The gasket’s exposure to radiation or UV rays

- Potential for corrosion or oxidation from the media or external factors

- The pH range of the media

- Industry standards or specification requirements including UL, MIL, NSF, WRAS, ANSI, and FDA